Shenyang Zkwell Corrosion Control Technology Co., Ltd

Address: Room 501, No. 1, Hunnan Road, Hunnan New District, Shenyang

Zip code: 110180

Tel: 86-24-83812820 83812821 24516448

Fax: 86-24-24515331

E-mail: business@zkwell.com.cn

Oil and gas well downhole corrosion led to a perforated tubing, casing damage, the serious influence the service life of oil and gas Wells, reduces the efficiency of oil and gas production, inspection and maintenance work of direct costs and indirect costs make the production cost is increased, the serious influence the economic benefits of oil and gas fields. So well downhole corrosion monitoring of oil and gas fields, and in a timely manner the right anticorrosion measures, improve the safety and reduce the economic loss of oil and gas well is necessary.

ZK9840 downhole corrosion on-line monitoring is division, the development of a set of innovative products, is currently the domestic first set of bad environment and corrosion characteristics of downhole developed a set of real-time monitor downhole corrosion speed dedicated system.

> > technical features:

, the inductance monitoring technology, measuring high sensitivity, stable and reliable;

, suitable temperature and pressure range, can be in any depth underground installation and recycling;

• real-time monitoring corrosion depth and corrosion rate, temperature and time;

State of losing electricity can save the data, ensure to restore power after data read properly;

After, take a number of ways: from downhole instrument, open the connection computer communication access;

Probe and collector one-piece structure, convenient for underground.

> > system structure:

Main body structure of the downhole inductance probe corrosion monitor probe, signal processing components, temperature measurement components, data storage module, battery pack, supporting software and other protection and connection parts. Structure diagram is as follows:

> > technical parameters:

Downhole pressure resistance, instrument: 40 mpa;

Reliable work of downhole temperature: less than 125 ℃;

• in data measuring density of 1 time/hour, can work continuously for 60 days.

• measurement resolution: 30 nm;

Data, data storage, storage for 60 days;

• instrument outside diameter is 42 mm, length is 820 mm.

> > data analysis:

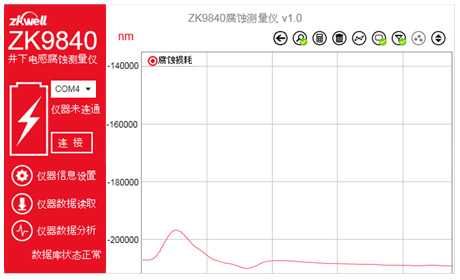

And instrument matching Zkwell Suite 2.0 special software for data management and analysis, as shown in figure for downhole testing inductance probe monitor in the 120 ℃ wax curve, in the heating stage, the corrosion loss value fluctuate, after constant temperature 120 ℃, the smooth curve. Every time a data collecting specimens were measured and the temperature compensation specimens do together, in the heating stage, measuring try piece and compensation will have a slight temperature difference, so the resistance ratio will fluctuate, constant temperature after a period of time, temperature difference is small, the data back to normal. The above test results show that the monitor full immersion in 120 ℃ wax, working state is stable, sensitive and reliable measurement.