Shenyang Zkwell Corrosion Control Technology Co., Ltd

Address: Room 501, No. 1, Hunnan Road, Hunnan New District, Shenyang

Zip code: 110180

Tel: 86-24-83812820 83812821 24516448

Fax: 86-24-24515331

E-mail: business@zkwell.com.cn

Pipeline on-line ultrasonic thickness measurement technology is based on the ultrasonic propagation characteristics, adopts the unique structure of the ultrasonic probe and acoustic waveguide design, the short wavelength and beam quality, realize the ultrasonic wave in a long path in the effective guidance and the transmission. The unique waveguide design can effectively buffer the continuous high temperature effects on piezoelectric ultrasonic transducer. Use of ultrasonic reflection principle of jet lag, can complete the high temperature continuous, real-time monitoring of pipe wall thickness.

A, technical features

1. The system installation without hole, without the coupling agent, and the high temperature of 600 ℃ pipeline can be continuous, real-time monitoring, measurement results are accurate, stable data;

2. Can be used on the pipeline welding cylinder bolt to fixed probe; Also can use clamp mode waveguide fixture fixed on the pipeline, tear open outfit is convenient, is not affected by other external factors such as human, space constraints;

3. System data can directly into the pipeline thickness enterprise widely used OTA5.0 corrosion monitoring and management system.

Second, the equipment technical parameters:

1. Measure the thickness range: 3 ~ 50 mm

2. The measurement accuracy: 0.05 mm

3. The waveguide length: 0 ~ 500 mm

4. The pipe wall temperature range: - 50 ~ 600 ℃

5. The instrument working temperature: system operating temperature - 40 ℃ ~ 70 ℃

6. The instrument working voltage: DC 14 ~ 28 V

7. Data acquisition frequency: 1 hour or more

8. Battery life: lithium electricity, 3 ~ 4 years

9. Transmission mode: the wireless transmission and cable transmission either

Three, the structure of the system:

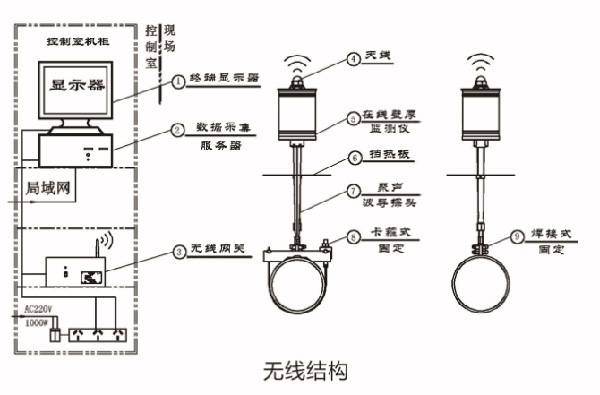

The structure of the pipeline on-line ultrasonic thickness measurement system is divided into wired and wireless structure, can be selected according to the user and site condition.

Wireless structure including: wireless wall thickness monitor, probe, waveguide clamp, pipe/welding stud form, wireless gateway, data analysis software, etc.

Cable structure include: wall thickness monitor, probe and waveguide jig, power supply and communication converter, cable, data analysis software, etc.

Four, the application case

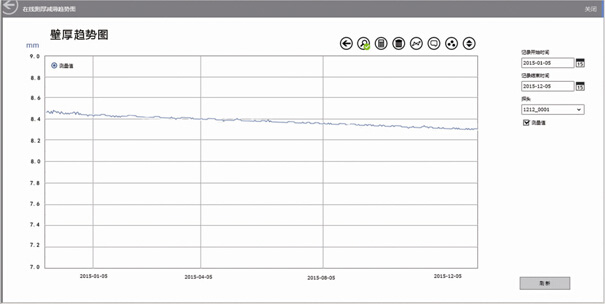

Some petrochemical enterprise respectively at the top of the roof water cooler inlet and is often the air cooler outlet installed ZK3810 online ultrasonic thickness measurement system, the installation of the waveguide probe used the way of the welding clamp, which does not need to be the scene when hot, equipment starts to run on the implementation of more convenient; System automatically collect data, the data into the terminal in wireless way, through OTA5.0 display data management software. Monitoring results show that the on-line monitoring in line with common ultrasonic thickness measurement results.

The system has been in sinopec yanshan petrochemical, yangzi petrochemical, qilu petrochemical, shengli oilfield production plant, petrochina fushun petrochemical, such as dalian petrochemical enterprise applications.

The technology for the division, national patented technology, will have broad application prospects in the field of petroleum and petrochemical.